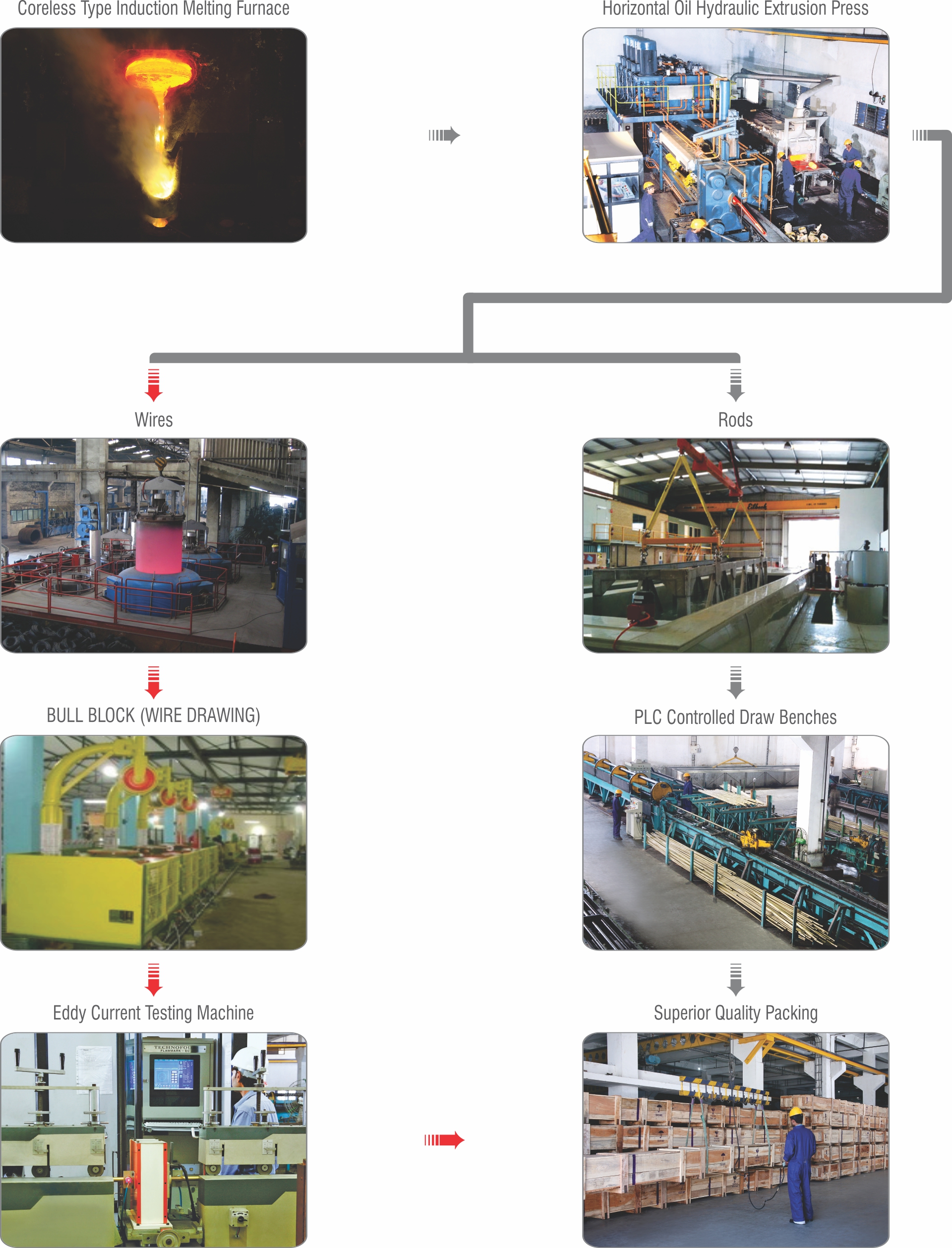

Infrastructure

We are backed by sound infrastructure, which adds to our productivity & competency in terms of product quality & quantity. Located in Jamnagar – Gujarat, our facility is well segregated into various departments such as manufacturing unit, storage unit and quality testing unit. Our manufacturing unit is stretched over a vast area of 100,000 sq. ft, which is equipped with requisite machines and hold the installed capacity of 6,000 tons extruded profiles per annum.

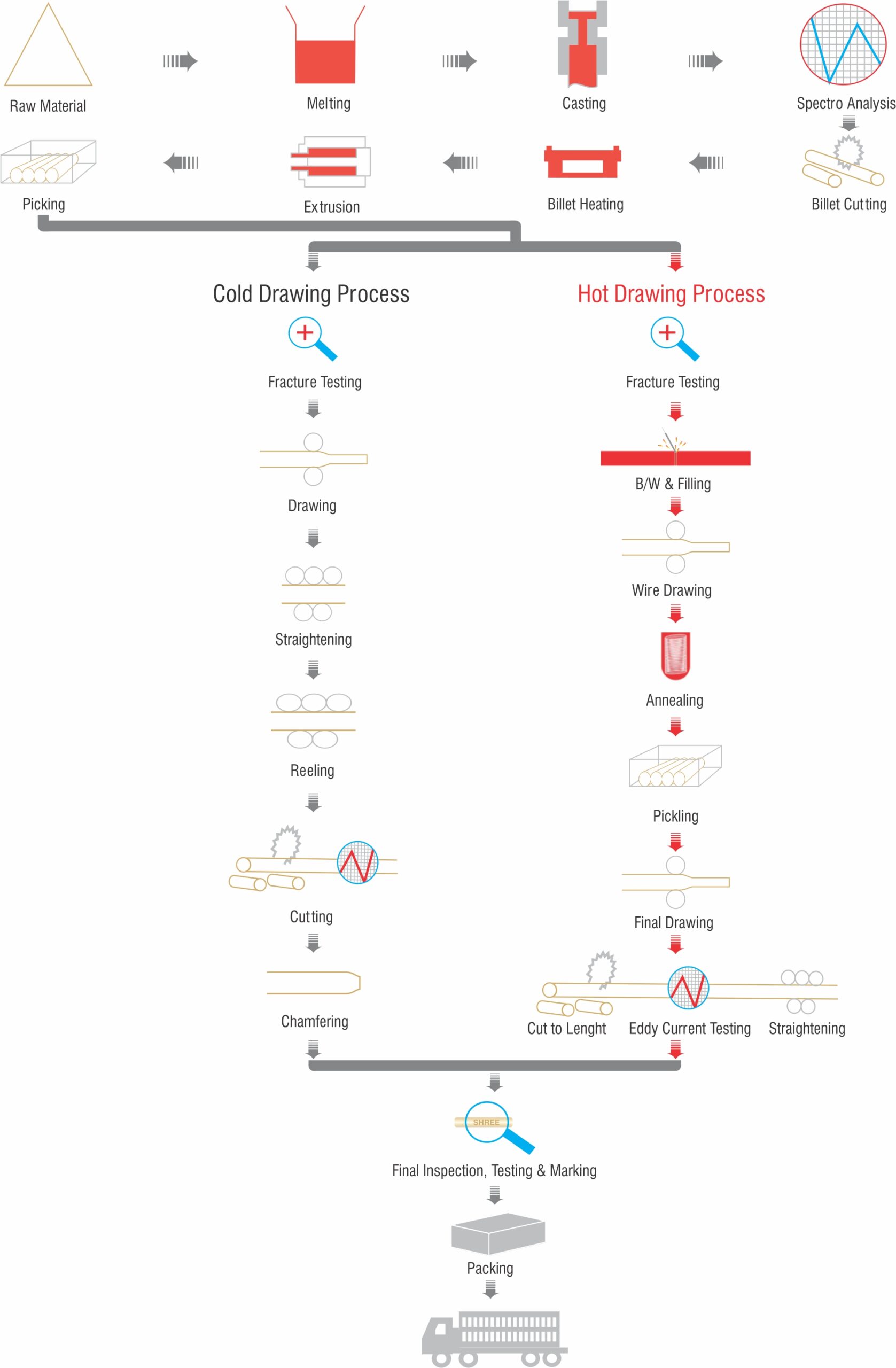

Process Flow Chart